Interconnected

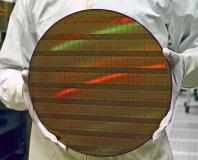

The wafer is then covered in a layer of insulation material. At this stage the transistors are actually complete, but they are completely isolated from each other. To make a functioning chip the transistors need to be able to talk to their hundreds of millions of siblings, and the next stage in the process - metal deposition - allows this.Initially three holes are etched at strategic points in the insulation layer above each transistor. The entire wafer is then placed into a copper sulphate solution and electroplated.

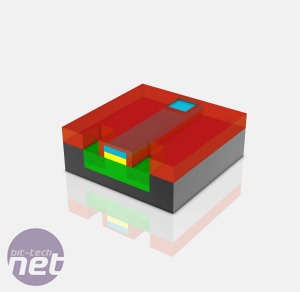

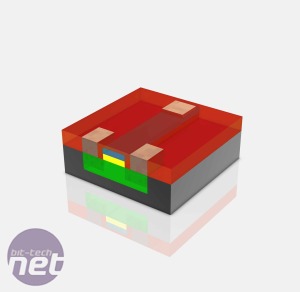

Left: The red layer is the newly added insulator, note the three tiny holes. Right: Electroplating, just like in GCSE chemistry

Electroplating a CPU wafer is exactly the same process many people will have either tried or seen done at school in chemistry class, and involves placing a negatively charged object (the cathode) into a metal salt solution. The metal salt contains positively charged ions which are attracted to the cathode (in this case, the wafer) and ‘reduce’ themselves upon the cathode to form an even metal layer over the object.

This leaves the entire wafer covered in a thin sheen of pure copper which now needs to be removed. This is done through a delicate polishing process which polishes the wafer back to the insulation layer, leaving copper still deposited in the three holes etched earlier in the process.

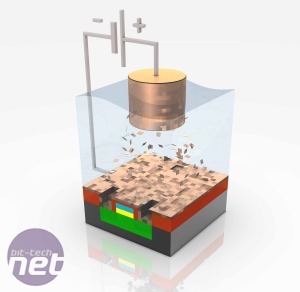

Left: Electroplating gives a perfectly smooth finish. Right: The transistor polished back to the insulator. Note the three holes are now filled with copper.

The transistors are now primed with metal contacts and just need wiring up; unfortunately wiring up hundreds of millions of microscopic transistors is a mind-bendingly complex task. It is also incredibly important, as this is where the performance crown can be won or lost - the stages up to this point are standard processes for making ICs and transistors.

It is the intricacies and complexities of the transistor interconnects of the chip that will eventually dictate individual performance and efficiency, so getting this stage correct is of paramount importance.

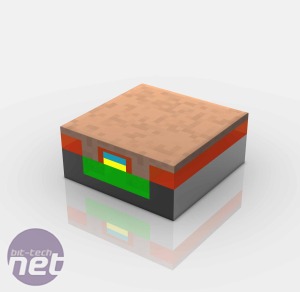

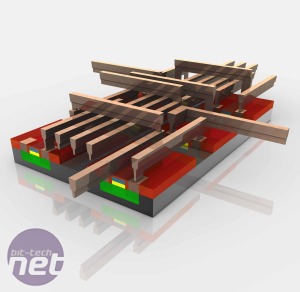

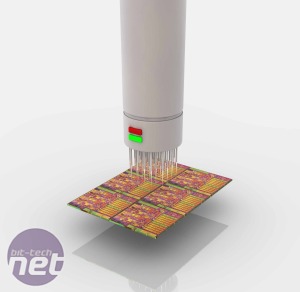

Left: This shows the interconnects between just six transistors - intricate is an understatement. Right: Basic quality control is also conducted at this point

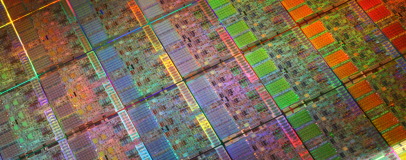

The interconnects are built up in levels with modern chips, with up to 30 levels of interconnects arranged above the surface of the chip in a bewilderingly complex fashion. Indeed, if you were so inclined, you could lever off the heatspreader on your CPU and take a look at the chip under a microscope. Having done this you would see what looks like a flat and smooth chip is in fact a complex 3d object, with Intel describing the intricate network of circuit interconnects as 'looking like a futuristic, multi-layered highway'.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.